Eiffel HiPower AW 68 Anti-Wear Hydraulic Oil - 205L Mineral Group 2

Eiffel HiPower AW 68 is a supreme performance anti-wear hydraulic oil formulated with high-quality Group 2 base stocks and balanced additive technology. Engineered for efficient operation in hydraulic systems under severe conditions, it provides superior anti-wear protection and oil film strength. This versatile oil is suitable for systems typically using non-anti-wear hydraulic oils as well, offering enhanced protection and performance across a wide range of applications.

Couldn't load pickup availability

Special Offer for New Online Customers: 10% OFF Your First Order! Use code: "WELCOME10" at checkout.

- Contact For Bulk Orders

- Quality Assurance (100%)

- Technical Support (5 Days/week)

- Features & Benefits

- Specifications

- Applications

- Typical Characteristics

Features & Benefits

• Outstanding thermal & oxidation stability helps in extending life of oil and filter.

• Superior demulsibility property of oil protects hydraulic systems from small quantities of moisture and

also separates readily from larger quantities of water.

• Excellent anti-wear properties and outstanding film strength provides exceptional equipment

protection, that not only results in fewer breakdowns but also helps improve production efficiency.

• Excellent protection from rust and corrosion of multi-metallurgy system components.

Specifications

Eiffel HiPower Hyd AW series meets or exceeds following International and Builder specifications:

• DIN 51524 Part 2 HLP type

• ISO 11158 (HM fluids)

• Denison HF-0 (T6H20C)

• VICKERS M-2950S, -I-286

Applications

Eiffel HiPower Hyd AW series are suitable for use in Hydraulic systems of Industrial and Mobile equipment.

• Suitable for use in Marine hydraulics, machine tools, mould injection machines and hydraulic presses.

• Applications where anti-wear lubricant is required: low charged gears, bearings, air compressors etc.

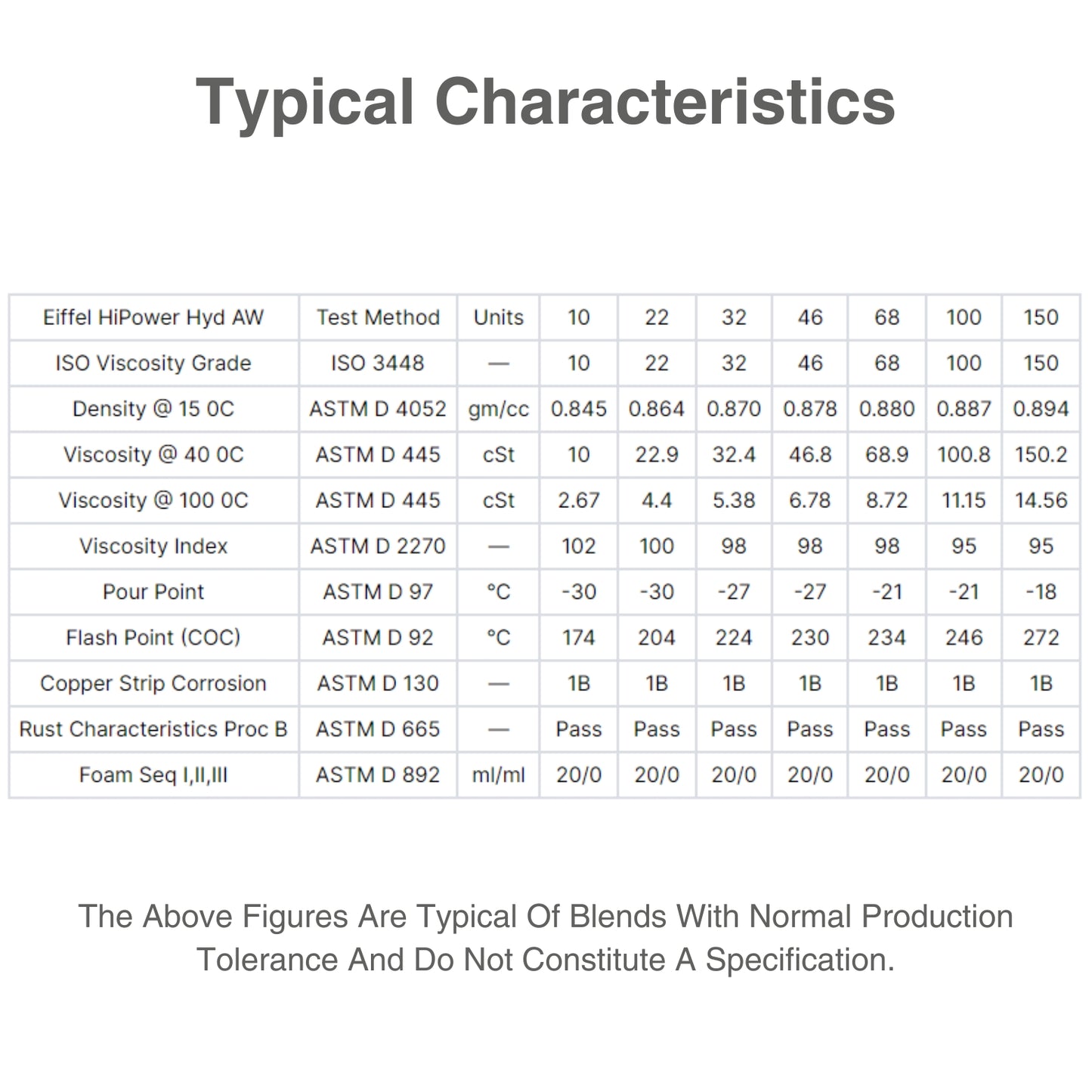

Typical Characteristics

| Eiffel HiPower Hyd AW | Test Method | Units | 68 |

|---|---|---|---|

| ISO Viscosity Grade | ISO 3448 | - | 68 |

| Density @ 15 0C | ASTM D 4052 | gm/cc | 0.880 |

| Viscosity @ 40 0C | ASTM D 445 | cSt | 68.9 |

| Viscosity @ 100 0C | ASTM D 445 | cSt | 8.72 |

| Viscosity Index | ASTM D 2270 | - | 98 |

| Pour Point | ASTM D 97 | °C | -21 |

| Flash Point (COC) | ASTM D 92 | °C | 234 |

| Copper Strip Corrosion | ASTM D 130 | - | 1B |

| Rust Characteristics Proc B | ASTM D 665 | - | Pass |

| Foam Seq I,II,III | ASTM D 892 | ml/ml | 20/0 |

The above figures are typical of blends with normal production tolerance and do not constitute a specification.

For further information, please contact: sales@eiffellubricants.com.au